Magento 2 Manage Stock for Subscription-Based Products

Are subscription stockouts killing your recurring revenue? It is because your Magento 2 manage stock system needs specialized configuration. This is necessary for subscription-based e-commerce products.

This article outlines inventory strategies to maintain a steady stock of subscribed products. It shares techniques to streamline fulfillment and automate stock control.

Magento 2 Manage Stock for Subscription-Based Products

Subscription Stockout Crisis Monitor

Real-time visualization of how stockouts impact your recurring revenue

Revenue at Risk

Monthly recurring revenue exposed

Affected Subscribers

Customers facing disruption

Churn Probability

Risk of permanent loss

Are subscription stockouts killing your recurring revenue? It is because your Magento 2 manage stock system needs specialized configuration. This is necessary for subscription-based e-commerce products.

This article outlines inventory strategies to maintain a steady stock of subscribed products. It shares techniques to streamline fulfillment and automate stock control.

Key Takeaways

Stock Decrement Timing

Configuration reserves inventory for future shipments

Dynamic Thresholds

Uses 3 critical measurements: demand, lead time, safety buffer

Backorder Activation

Prevents disruptions to subscription services during restocking

Supplier Integration

Setup uses 2 proven methods: API connections and EDI

Performance Monitoring

Advanced reporting to investment levels

- Stock decrement timing configuration reserves inventory for future shipments.

- Dynamic thresholds use 3 critical measurements: demand, lead time, and safety buffer.

- Backorder activation prevents disruptions to subscription services during restocking.

- Supplier integration setup uses 2 proven methods: API connections and EDI.

- Performance monitoring involves advanced reporting to investment levels.

- How to Manage Stock Levels in Magento for Subscribed Products?

What Are Subscription-Based Products in Magento 2?

Subscription-based products are items customers buy on a recurring schedule. Examples include:

Monthly coffee deliveries

Quarterly skincare boxes

Annual software licenses

Unlike traditional ecommerce purchases, customers commit to receiving products over extended periods. This creates contractual obligations for businesses. They must ensure product availability for future deliveries, alongside current orders.

Higher LTV than one-time buyers

More predictable revenue

Lower acquisition cost

So, these products generate predictable revenue, yes. But they demand sophisticated Magento inventory planning.

Why Is Stock Management Critical for Subscriptions?

Subscription inventory management differs from traditional ecommerce systems. It creates unique challenges that compound business risks across billing cycles.

I. Common Stock Management Challenges

Subscription inventory management operates on different principles from standard ecommerce stock systems.

Temporal stock allocation

Reserve future inventory without reducing current product availability displays.

Multi-cycle demand forecasting

Calculate requirements across 3 to 12 billing periods.

Buffer calculations

Adjust safety product stock based on subscription volatility coefficients.

Bi-directional stock flows

Handle both subscription additions and cancellation-driven returns.

Cross-channel inventory conflicts

Prevent one-time orders from consuming reserved subscription stock.

How to Manage Stock Levels in Magento for Subscribed Products?

Implement a sophisticated 4-layer stock architecture to ensure consistent subscription fulfillment

Click on a layer to explore

Each stock layer serves a specific purpose in maintaining subscription continuity

Real-time Allocation

Dynamic stock assignment based on subscription priorities and order velocity

Protection Levels

Multi-tier safeguards prevent subscription disruptions during peak periods

Auto-rebalancing

Intelligent redistribution optimizes stock levels across all layers

1. Configure Advanced Stock Architecture

I. Subscription Product Identification Matrix

Create hierarchical product classification systems. Enable granular inventory management control across subscription types.

Advanced Tagging Method:

- Primary subscription attribute: Boolean flag for recurring products.

- Frequency classification: Weekly, monthly, quarterly, and annual categories.

- Demand volatility index: High, medium, low variance classifications.

- Supplier reliability coefficient: Lead time consistency ratings.

- Cross-sell dependency mapping: Connecting related product stock inventory.

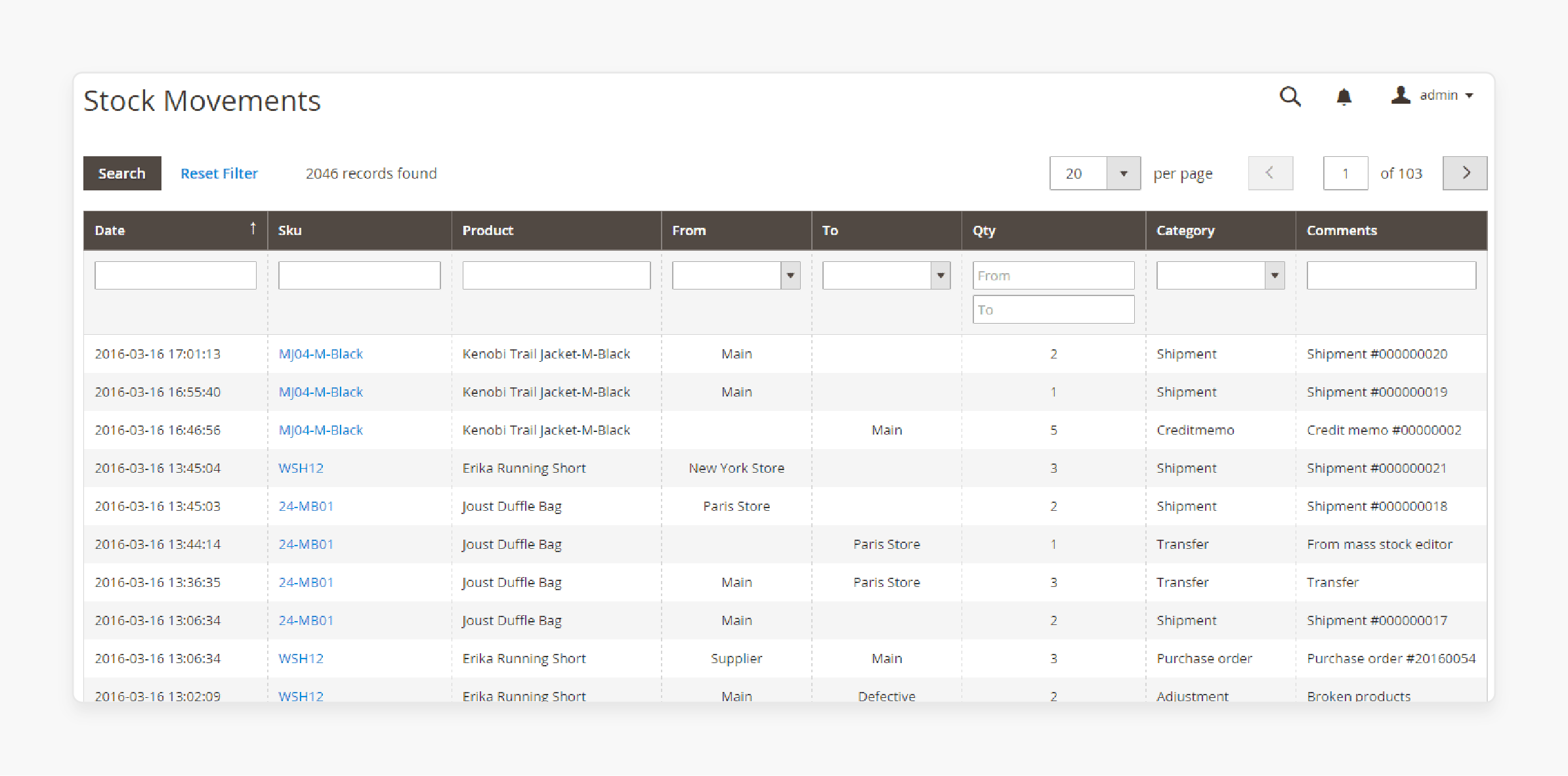

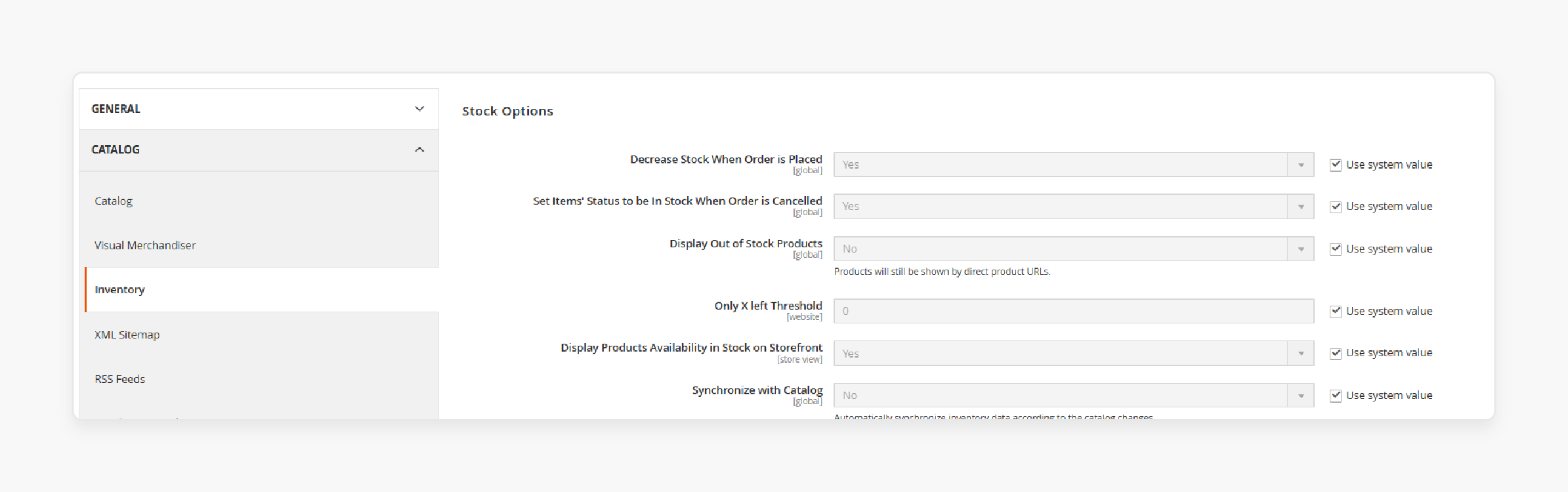

II. Stock Decrement Logic

Configure intelligent stock reduction timing that aligns with subscription fulfillment.

Navigation path: Stores > Configuration > Catalog > Inventory > Stock Options

Advanced configuration settings:

- Set 'Decrease Stock When Order Placed' to 'No' for subscription items.

- Enable 'Return Credit Memo Item to Stock' for returns.

- Configure 'Display Out of Stock Products' to 'No' for subscription items.

- Set up custom stock status logic using product attributes.

2. Set Up Threshold Calculations

I. Statistical Stock Level Calculations

Use quantitative methods to determine product stock thresholds based on subscription data analysis.

Mathematical Framework:

Minimum Stock Formula

Least Stock = (Average Demand × Lead Time) + Safety Stock

Safety Stock Formula

Safety Stock = Z-Score × √(Lead Time × Demand Variance)

Calculated Thresholds

Safety Stock

0

units buffer

Minimum Stock

0

reorder point

Maximum Stock

0

optimal ceiling

Threshold Configuration Variables:

| Variable | Calculation Method | Typical Range |

|---|---|---|

| Lead Time Multiplier | Historical supplier data | Variable range |

| Demand Variance | Rolling standard deviation | Variable range |

| Service Level Target | Business risk tolerance | High percentage range |

| Seasonal Change | YoY demand comparison | Variable multiplier |

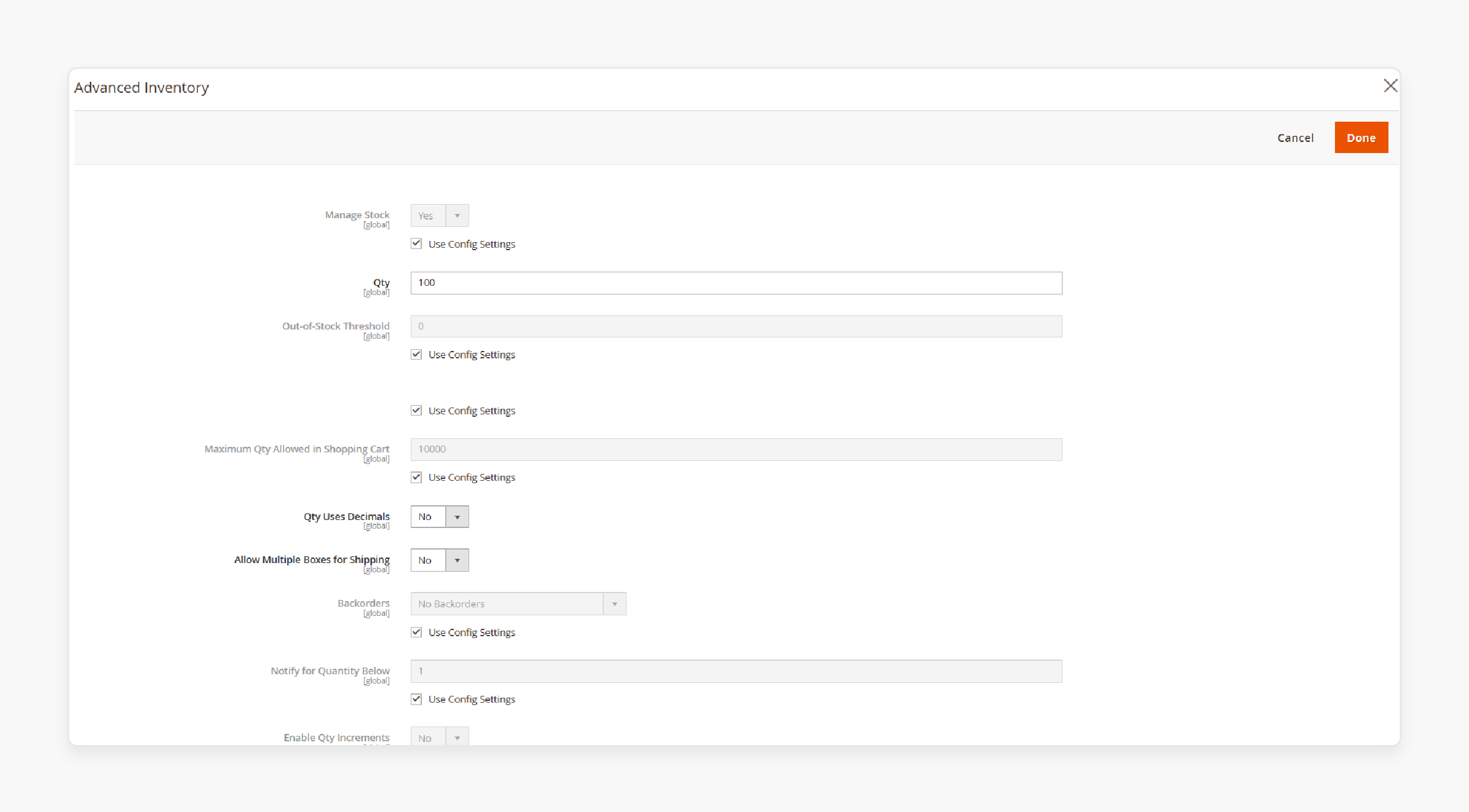

II. Alert Configuration Method

Navigate to: Catalog > Products > [Product Name] > Advanced Inventory

- • Set 'Notify for Quantity Below' using calculated thresholds.

- • Configure alert levels: Warning and Critical thresholds.

- • Set up escalation for different stakeholder groups.

- • Enable buying order triggers at predetermined levels.

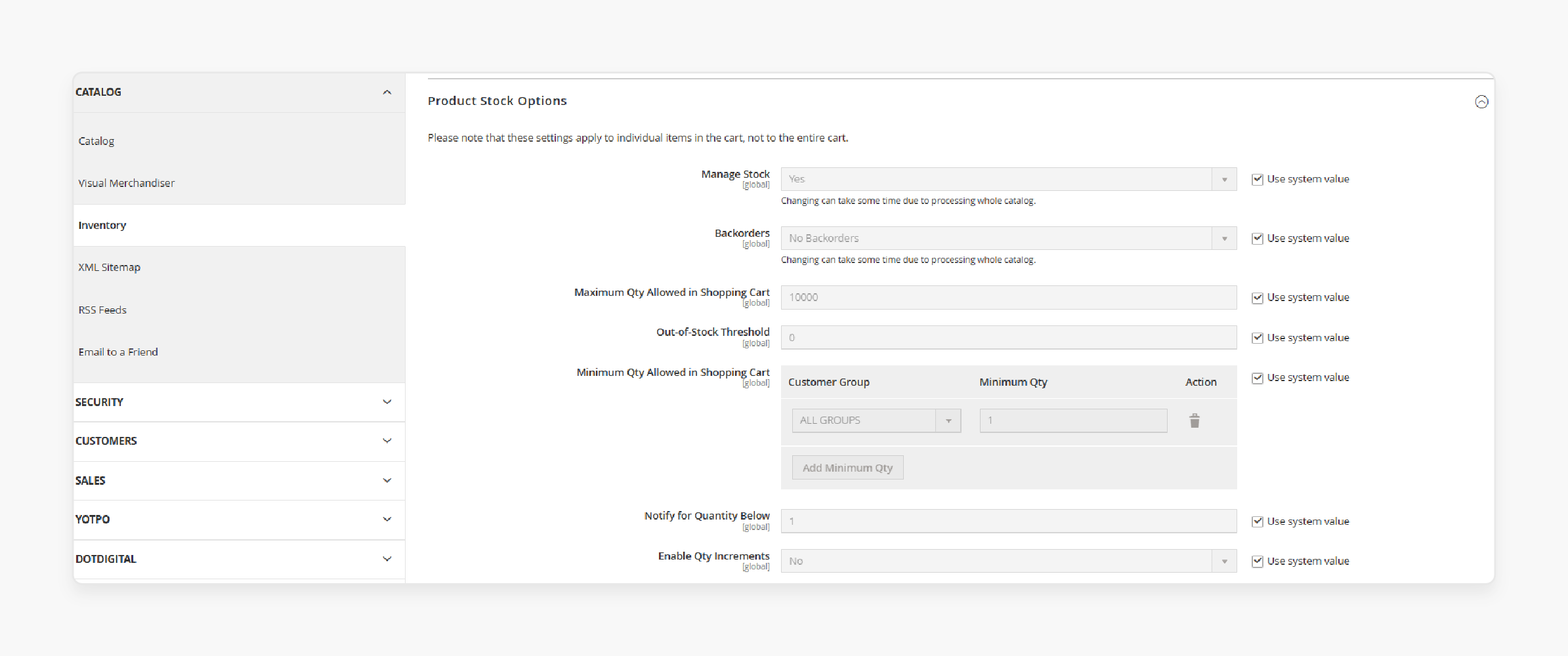

3. Set Up Backorder Architecture

I. Intelligent Backorder Logic

Configure sophisticated backorder policies that maintain subscription continuity in your storefront. At the same time, remember to manage customer expectations.

Configuration Path: Stores > Configuration > Catalog > Inventory > Product Stock Options

Advanced backorder settings:

- Set 'Backorders' to 'Allow Qty Below 0 and Notify Customer.'

- Configure 'Largest Qty Allowed in Shopping Cart' to unlimited for subscriptions.

- Enable 'Qty Increments' with a value of 1.

- Set up custom backorder allocation priorities.

II. Customer Communication

Develop messaging systems that provide transparent backorder status updates.

- Order confirmation templates: Include estimated fulfillment dates based on supplier schedules.

- Proactive delay notifications: Trigger notifications before expected shipment delays.

- Alternative product suggestions: Offer substitute items with similar profiles.

- Compensation: Discounts or service credits for extended delays.

4. Set Up Replenishment Intelligence

I. Supplier Integration Architecture

Set up multi-channel supplier connectivity that inventory management synchronization.

REST API Integration

Real-time inventory synchronization with modern suppliers using RESTful endpoints

Use Case

Magento inventory sync

Setup Complexity

Key Features

- Real-time data synchronization

- JSON/XML data formats

- OAuth 2.0 authentication

- Rate limiting support

< 1 sec

Update Speed

Implementation Code Sample

// REST API Integration Example

$client = new \GuzzleHttp\Client();

$response = $client->request('GET', 'https://api.supplier.com/inventory', [

'headers' => [

'Authorization' => 'Bearer ' . $token,

'Accept' => 'application/json',

]

]);

$inventory = json_decode($response->getBody(), true);API Integration Methods:

| Integration Type | Use Case | Setup Complexity |

|---|---|---|

| REST API | Magento inventory sync | Medium |

| EDI Connections | Large-scale B2B suppliers | High |

| FTP/SFTP Feeds | Scheduled batch updates | Low |

| Webhook Notifications | Event-driven updates | Medium |

II. Replenishment Calculations

Configure reordering based on subscription forecasting models.

- • Lead time: Calculate order timing using supplier performance data.

- • Seasonal demand modification: Change reorder quantities based on historical patterns.

- • Growth trajectory planning: Increase product stock levels to subscription acquisition rates.

- • Multi-SKU coordination: Synchronize related product replenishment cycles.

Replenishment Schedule Matrix:

Reorder Point = (Average Daily Demand × Lead Time Days) + Safety Stock

Economic Order Quantity = √((2 × Annual Demand × Order Cost) / Holding Cost)

5. Conduct Performance Monitoring

I. Monitoring Setup

Set up tracking systems that provide actionable data for inventory management adjustments.

Key Performance Indicators

Stock turnover velocity

Inventory management investment measurements

Target: 15x per year

Fulfillment rate consistency

Percentage of on-time subscription deliveries

Industry avg: 94%

Carrying cost

Balance between service levels and capital use

Optimal: 15-20%

Supplier performance data

Lead time accuracy and quality measurements

Score: 4.2/5.0

Demand forecast accuracy

Prediction model effectiveness measurements

ML Model v2.3

Real-time Updates

Performance Trend Analysis

II. Modification Protocols

Configure threshold modifications based on performance data analysis.

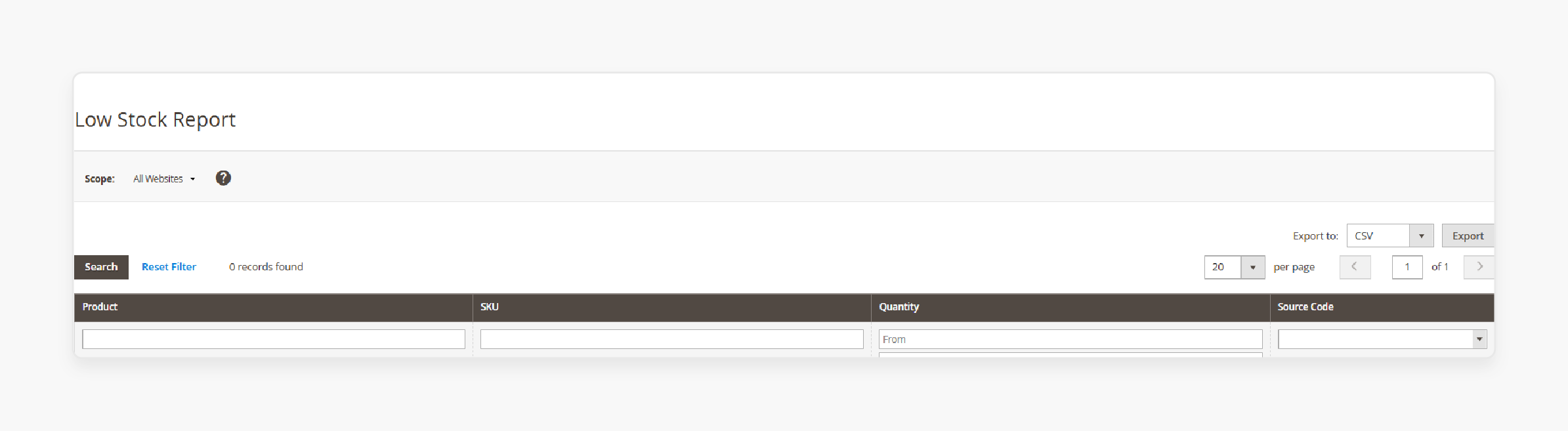

Navigation: Reports > Products > Low Stock

Advanced reporting features:

- • Custom date range analysis for seasonal patterns.

- • Supplier performance correlation with product stock levels.

- • Customer churn analysis related to fulfillment delays.

- • Profitability impact assessment across different stock management strategies.

6. Test and Verify

I. Simulation Testing Protocols

Verify all configuration changes using testing approaches before deploying them to production.

Testing Progress Dashboard

Tests Passed

In Progress

Pending

Testing Sequence:

Environment isolation

Use a staging environment identical to production.

Data replication

Copy the current subscription and magento inventory data.

Scenario simulation

Test various product stock level conditions and supplier delays.

Performance validation

Measure system response times under load conditions.

Integration verification

Confirm that all third-party connections function.

II. Backorder Testing

Testing backorders maintains customer satisfaction during stock shortages.

Test case matrix:

Zero stock scenarios

Verify customer notifications and order processing.

Partial fulfillment logic

Test split shipment handling and communication.

Restocking

Confirm allocation when inventory arrives.

Exception handling

Test system behavior during supplier failures or delays.

FAQs

Use the coefficient of variation analysis across historical data. Apply seasonal multipliers: Q4 holidays, summer lulls, back-to-school spikes.

Seasonal Multipliers:

Q4 Holidays

1.4x

Summer

0.8x

Back-to-School

1.2x

Yes, create custom inventory attributes for VIP, Premium, and Standard allocations. Set percentage-based reservations through Magento 2 admin configuration for each tier level.

Recommended Tier Allocations:

Calculate using the Economic Order Quantity (EOQ) formula adjusted for subscription velocity. Weekly reorders are suitable for high-volume products. Set up monthly reorders for standard items.

High-Volume Products

Weekly

≥ 1000 units/month

Standard Products

Monthly

< 1000 units/month

Create separate demand forecasting models for gift vs. self-purchase patterns. Gift subscriptions show spikes in Q4 and drops in Q1.

Negotiate separate supply agreements with priority allocation clauses. It helps manage Magento 2 inventory levels. Consider dedicated subscription-based suppliers for critical products.

Supplier Strategy Matrix:

Shared Suppliers

✓ Cost efficiency

✗ Competition for stock

Dedicated Suppliers

✓ Guaranteed allocation

✗ Higher costs

For virtual products, disable physical inventory management. Maintain subscription allocation counts. Set unlimited stock quantities and track active license counts through custom attributes.

Virtual Product Configuration:

Yes, subscription products need lower out-of-stock threshold values to trigger earlier warnings. Set thresholds at higher buffer levels since subscription customers expect consistent availability.

Threshold Comparison:

Regular Products

10%

of total stock

Subscription Products

25%

of total stock

Higher thresholds = Earlier warnings = Better availability

Summary

Magento 2 manage stock requires configuration and advanced monitoring for subscription success. These approaches stay consistent with fulfillment while maximizing inventory management performance.

- Mathematical threshold calculations using demand variance and lead time data.

- Supplier API integrations for replenishment and synchronization.

- Backorders deployment with customer communication and priority allocation.

- Performance monitoring using advanced data analysis and modification protocols.

- Configuration testing using simulation and validation frameworks.

Need reliable infrastructure for your subscription inventory management? Explore managed Magento hosting to ensure your business runs without interruptions.